New Limonite Ore Mobile Crushing Plant System Is Your Best Choose

What’s Involved in Limonite Ore Dressing Process?

2024年10月25日 The main purpose of limonite ore dressing is to effectively extract iron Technologies such as magnetic separation, flotation and gravity concentration can improve 5 天之前 This setup is a rock limonite ore dressing plant that mainly separates and upgrades limonite concentrate by crushing, screening, grinding, and gravity separation 1 Crushing Limonite Ore Dressing JXSC Machinery2024年10月25日 JXSC effectively separates limonite ore from impurities by combining gravity separation, magnetic separation and flotation technology to obtain highgrade oreJXSC Beneficiation Method Solves Difficult 2024年9月24日 There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and Crushing Plant Design and Layout Considerations 911

.jpg)

Limonite Ore Processing Technology Fote

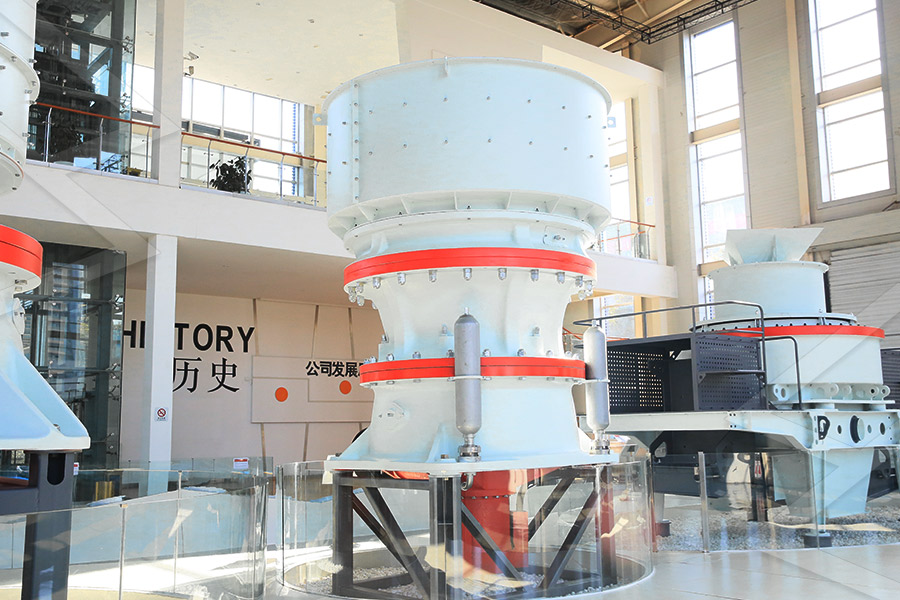

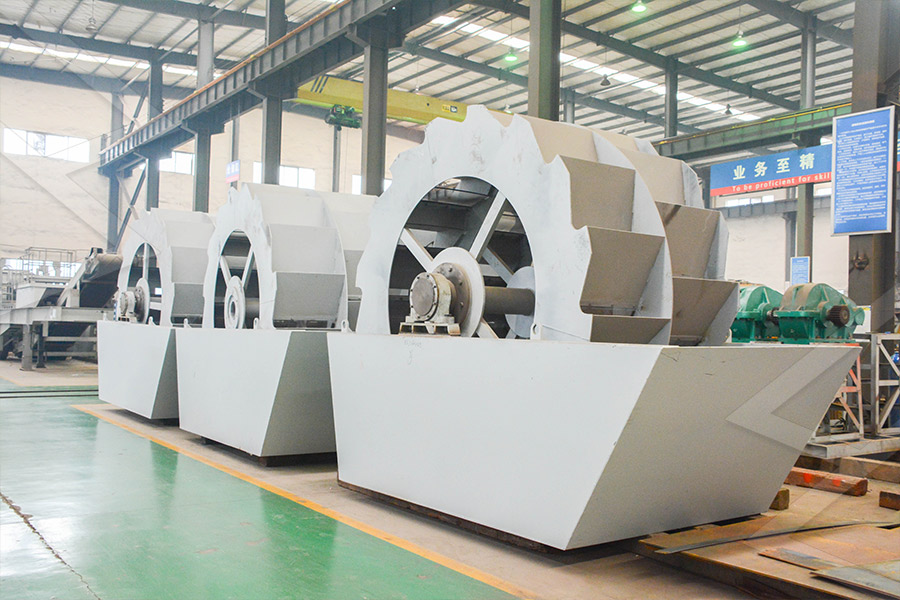

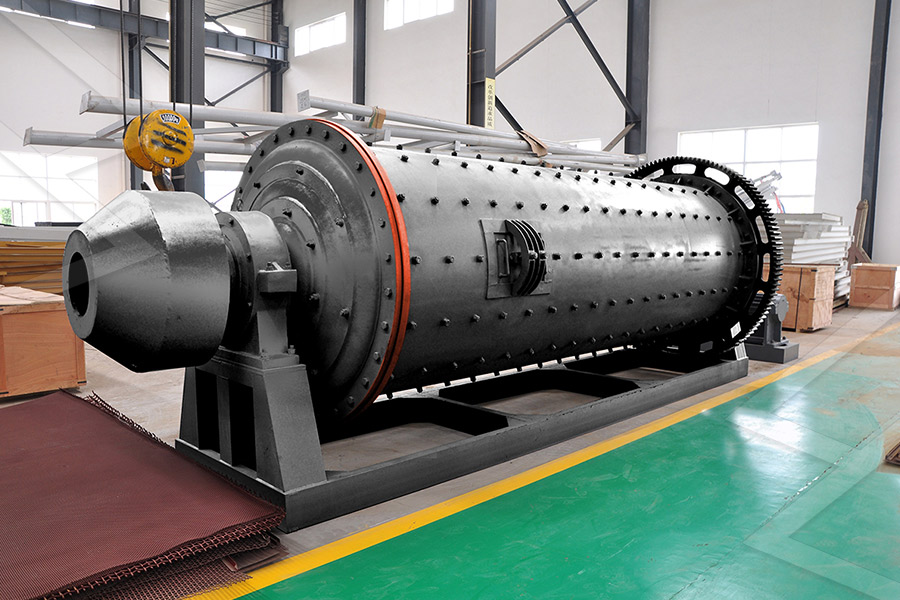

2019年8月8日 Limonite ore processing plant of Fote Machinery is mainly composed of jaw crusher, ball mill, spiral classifier, magnetic separator, dryer, and other equipment The process of limonite beneficiation production line is Unlock the full potential of your quarry operation with mobile crushers from thyssenkrupp Polysius Our stateoftheart equipment offers superior performance, efficiency and flexibility, enabling you to achieve maximum Mobile crushing plants thyssenkrupp Polysius2023年8月15日 In mineral processing, how to efficiently extract limonite has become a problem that mineral processing experts need to solve This article will introduce you to five common limonite beneficiation methods5 Limonite Beneficiation Methods JXSC Machine2022年1月1日 There is now a new generation of mobile crushing and screening plant systems which have been developed based on the motivation of reducing truck haulage Newly Comminution and classification technologies of iron ore

.jpg)

Limonite Iron Ore Processing and Beneficiation Plant

2023年12月29日 Limonite Iron Ore Processing and Beneficiation Plant Equipment, Find Details and Price about Hematite Dressing Plant Hematite Crushing Plant from Limonite Iron Ore 2024年10月25日 The specific beneficiation technology used depends on the characteristics of the ore, such as its chemical composition, mineralogy and physical properties; by understanding the characteristics of each ore and the Various Types Of Iron Ore Beneficiation Processes4 天之前 Small portable/ mobile crusher plants can easily crush various materials and have strong flexibility, bringing new conveniences to the user These portable rock crusher plants offer efficient solutions for smalllarge Small Portable Crusher plant JXSC Machinery2016年3月11日 Where fine crushing should stop and grinding begin is controversial and is influenced greatly by personal opinions and experiences Often, this break point will be different if consideration is being given to a new Crushing Plant Flowsheet DesignLayout

What Is Mobile Crushing Plant? Flexible Crushing Solution

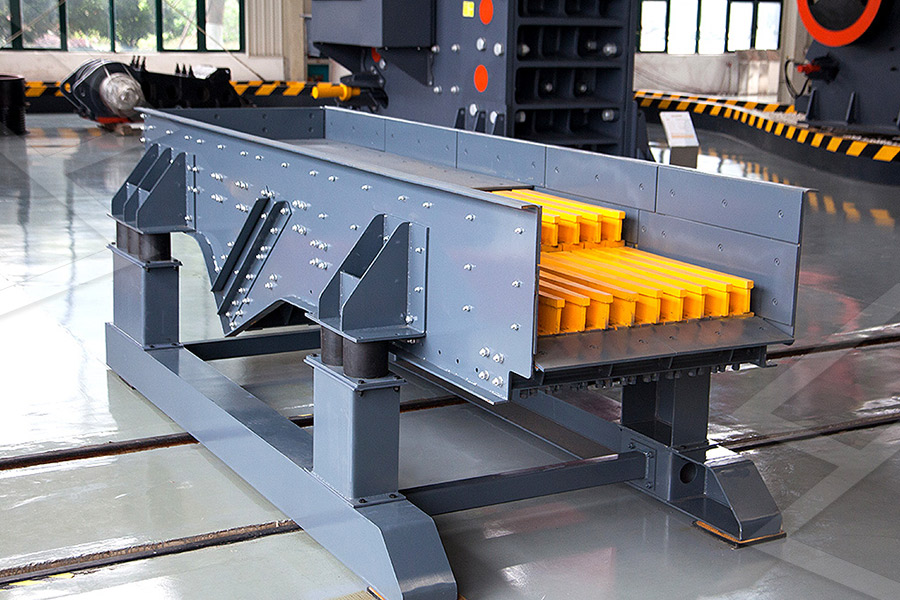

What is mobile crushing plant? Mobile crushing plant is equipment that can implement multistage crushing and screening processes to turn large block raw material into smaller finished aggregate material of various sizes and particles Equipped with tiretype or crawlertype chassis, mobile crushing and screening plant can be easily transferred between different working sites1 天前 1 The dump truck feeds the raw ore into the hopper and the vibrating feeder The vibrating feeder feeds evenly to the jaw crusher, which crushes large rocks to less than 200mm 2 The jaw crusher output is sent to the transfer bin through the belt conveyor, and an electromagnetic vibrating feeder is installed below it Convey the material less than 200mm to Iron Ore Beneficiation Plant, Iron Ore Magnetic Separation 2024年10月25日 Common types of iron ore are magnetite, hematite, limonite and siderite Among them, hematite, as a weak magnetic iron ore, has uneven particle size and high content of fine particles Hematite ore is an important iron ore resource in my country In the early 1960s, hematite ore was mainly processed by roastingmagnetic separation and single 4 Kinds of Hematite Ore Beneficiation Processes How To ChooseManganese ore crushing process The manganese ore processing technology mainly includes three processes: crushing, grinding and beneficiationDuring the crushing process, the threestage closedcircuit crushing is the most modern and suitable for the crushing of high hardness manganese ore, which can complete the work of ore crushing and Manganese ore crushing equipment processing technology

Limonite crusher Mining Quarry Plant

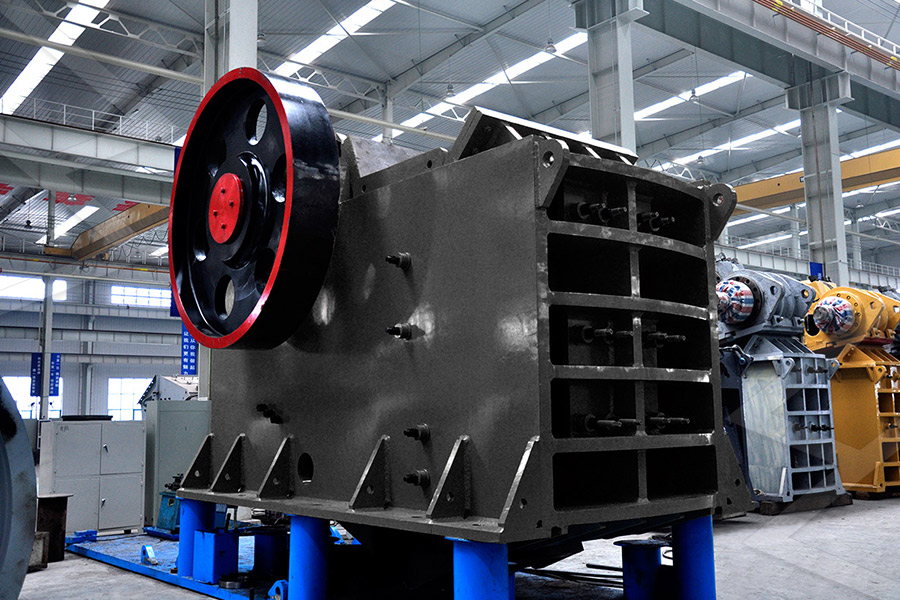

2013年9月10日 Limonite crushing plant includes limonite crushing equipment, limonite milling equipment, limonite screening and Limonite Crusher, Limonite Grinding Mill, Limonite Crushing Limonite is an ore consisting in a mixture of hydrated 6 天之前 Tin(Cassiterite) ore processing refers to the process of extracting tin from ore Gravity separation, magnetic separation and flotation are mainly used to grade tin concentrate and remove other impurities In order to achieve high efficient, lowcost beneficiation flow, JXSC will custom process and equipment according to ore characteristicsTin Ore Processing Plant JXSC Machinery2024年10月13日 Mobile crushing plants have been applicable in a range of industries However, the working processes of it can differ significantly depending on the industry and the specific requirements of the materials being processed Next, you can explores how mobile crushing and screening plants are adapted to meet the unique demands of various industriesHow Does A Mobile Crusher Plant Work? aimixgroup2024年10月25日 The selection of appropriate manganese ore beneficiation technology depends on factors such as the characteristics of the original ore, the desired product grade and recovery rate, and the scale of production JXSC Five Kinds Technology Of Manganese Ore

.jpg)

Limonite Ore Processing Technology Fote

2019年8月8日 The Introduction of Limonite Ore Processing Plant Limonite ore processing plant of Fote Machinery is mainly composed of jaw crusher, ball mill, spiral classifier, magnetic separator, dryer, and other equipment The process 2022年1月1日 The three primary and secondary crushing stations each crush 5000 tons of ore an hour (t/h) into particles smaller than 150 mm This material is then conveyed to a 250,000 t surge stockpile prior to being fed into the processing plant When the ore is fed into the processing plant it first enters the scrubbers, before being sent to wet minution and classification technologies of iron ore6 天之前 Feeding stage: First, use a vibrating feeder with sieve bars to remove largesized stones Washing stage: Smaller particles enter the trommel scrubbers to clean the diamond ore The ore washing machine has two layers of screens of 2mm and 25mm, which mainly separate 225mm particles Screening stage: Because the 225mm material is likely to be mixed with Diamond Wash Plant Equipment JXSC Machinery2023年6月2日 Choose this process, you can choose magnetic separationcation reverse flotation process or magnetic separationanion reverse flotation This process is mainly aimed at problems such as the difficulty in improving the grade of some iron ore concentrates and the high content of silica impurities in the concentratesMineral Processing Technology of Magnetite, Hematite and Limonite Ore

.jpg)

What Are The Benefits of Using A Mobile Crushing Plant?

2024年9月18日 Key Features and Benefits of Track Mobile Crusher Plant High Mobility: Track type mobile crushing machine can navigate difficult terrain and reach otherwise inaccessible areasIt is particularly beneficial in mining operations where the work site changes frequently, and in construction sites with uneven ground2024年10月25日 The vertical shaft impact sand making machine can choose different crushing cavity types of “stone hitting stone” or “stone hitting iron” For granite, the hardness is relatively large, so it is not suitable to choose the “stone hitting iron” cavity type, because the surrounding guard plate is easy to wear and cause the cost of The Top 5 Must Know Granite Crushers (With GIF) JXSC Jaw mobile crushing plant is also known as a coarse crushing tire mobile crushing station Therefore, it is usually used for primary crushing equipmentThe small mobile jaw crusher plant adopts an integrated operation method, which eliminates the installation of complex site infrastructure and auxiliary facilities The overall structure of the mobile jaw crushing station is Mobile Crusher Plant in The Philippines Wheeled Or 4 天之前 Manual models require an operator to manually feed and control the crushing process, while semi and fullyautomatic models are more efficient and often include automatic feeding and discharge systems JXSC provides six types of glass bottle crushers: smalllarge scale, mobile and cabinettype, hammer crushing machinesGlass Bottle Crusher JXSC Machinery

How to choose mobile crushing plant LinkedIn

2023年3月13日 Choosing the right mobile crushing plant depends on several factors, such as the type and size of the material you need to crush, the desired output size, and the budget you have for the equipment2023年1月19日 The mobile tracked crushing plant incorporates jaw crusher and cone crusher for mobile applications, with the following superior features: a big nominal feed opening and a sturdy structure Perfect Match with the Mobile Conveying System:Large Scale Tracked Stone Crusher, Mobile Ore Crushing Plant 6 天之前 1 Feeding: Excavator or truck send raw ore into the raw material hopper, through vibrating feeder evenly feeds trommel screen The vibrating feeder with grizzly bar, gap 75mm, and over 75mm rock will be sent to the Chrome Processing Plant, Chrome Wash Plant, 2023年6月13日 Limonite ore is a widely occurring iron ore resource characterized by its high content of iron oxide and variable mineral composition Due to its complex nature, effective beneficiation techniques What Are The Beneficiation Processes Of Limonite? —— 4

.jpg)

Four Points To Improve Tin Ore Flotation Recovery Rate

2024年10月25日 The collision between particles and air bubbles plays an important role in the selectivity and recovery of tin ore flotation When the bubbles and tin mineral particles approach each other and collide, due to the physical adsorption characteristics of the surface of the tin mineral particles, a large energy difference is generated between the bubbles and the tin 2024年10月26日 Manganese ore beneficiation is extracting valuable minerals and removing impurities from manganese ore It usually includes crushing, grinding, washing, gravity separation, flotation or magnetic separation to improve the grade and concentration of manganese The manganese ore process is used to beneficiate manganese oxide and carbonate oreManganese Processing Plant, Manganese Beneficiation 2023年1月30日 limonite ore The extraction of gold from limonite ore typically involves the following steps: 1Crushing and grinding the ore to reduce its size and increase the surface area for subsequent How to extract gold from limonite ore LinkedIn2022年4月26日 The optimization capabilities for crushing plants comprise a system solution with the twofold application of 1) Utilizing the simulation platform for identification and exploration of operational (PDF) Optimization Capabilities for Crushing Plants

.jpg)

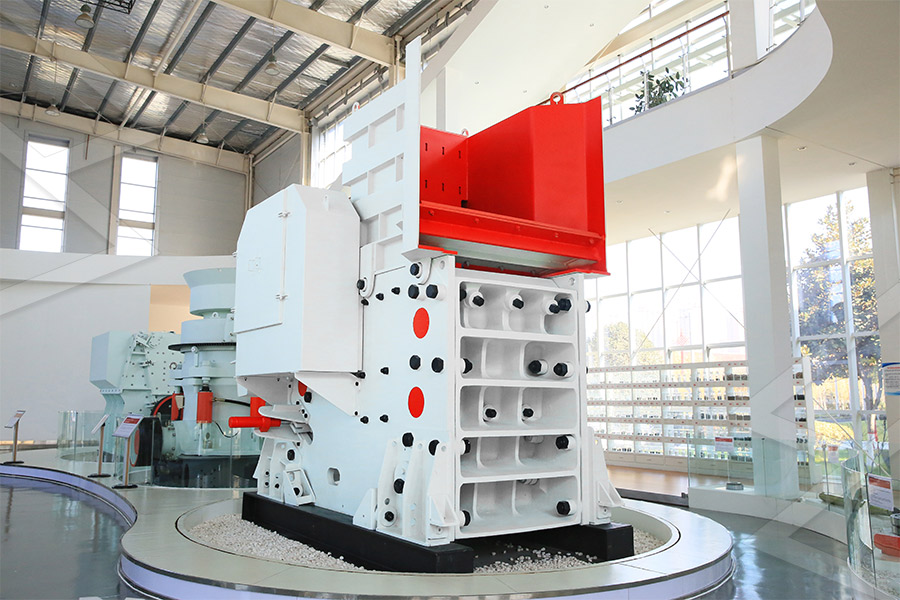

Red Limonite Ore Beneficiation Plant Crushing Grinding

High quality Red Limonite Ore Beneficiation Plant Crushing Grinding from China, China's leading Red Limonite Beneficiation Plant product, with strict quality control Limonite Ore Beneficiation Plant factories, producing high quality Grinding Limonite Beneficiation Plant products6 天之前 Types: Small portable jaw crusher with vibrating screen; Small portable jaw crusher with belt conveyor; Small portable hammer crusher; Application: The small portable rock crushers widely used to crush and screen various rocks, stone, aggregates, construction materials and ores, including limestone, granite, marble, gypsum, basalt, iron ore, copper ore, etc crushing Small Portable Rock Crushers JXSC MachineryThere are 10 Crushing Plant for sale in Australia from which to choose Overall 91% of Crushing Plant buyers enquire on only used listings, 6% on new and 896% on both new and used Crushing Plant items Buyers usually enquire on 182 different Crushing Plant classifieds before organising finance Crushing Plant are listed between $7,500 and Crushing Plant Largest choice of New Used in Australia2023年2月3日 The best iron ore mobile crushing plant is one that efficiently and effectively processes the iron ore to produce highquality end products that meet the needs of customers There is no one "best What is the best iron ore mobile crushing plant? LinkedIn

A Guide to Mobile Crushing Plants: Types,

2023年2月24日 Mobile crushing plants have revolutionized the way materials are extracted and processed in various industries They offer flexibility, mobility, and efficiency that cannot be achieved with traditional stationary crushing 2024年10月25日 This type of ore is generally processed by flotation, which concentrates the gold in the nonferrous ore concentrate and then recovers the gold during the smelting process Gold can be obtained by cyanidation from Gold Extraction Methods From Three Types of 2024年10月24日 These portable crushing machines are also available on rental basis for suitable longterm crushing contract for more than 23 years The crushing plant is available on per ton crushing charge basis and the available plant is of minimum 200 TPH which is capable of crushing minimum 1500 to 3000 MT per day depending upon the hardness and feed Portable Mobile Stone Crushing Plant Rent Sales2023年10月20日 Discover essential information on China's leading mobile crushing plants, their features, and market dominance Luton Heavy Industry Equipment, Co, Ltd, is a new jointstock enterprises integrated with research and development, production, sales, as well as service After 20 years of innovation and development, Luton has three major Key Insights on China's Top 10 Mobile Crushing Plants

.jpg)

Wet Pan Mill JXSC Machinery

5 天之前 The wet pan mill is the full name of the wet pan grinding mill, gold pan mill, or wheel pan millAccording to the different applications, it is divided into the gold mill, amalgam mill, iron mill, and electric mill; According to the different structure, it is divided into single pan mill, double pan mill and three pan mill2022年11月9日 The new HPAL plant will process nickel limonite ore into Mixed Hydroxide Precipitate (“MHP”) product with the planned annual production capacity of around 60,000 tonnes of nickel in MHP MHP can then be processed into materials for battery components, such as for electric vehiclesPT Vale and Huayou Show Sustainability Commitment by 3 天之前 1 Feeding crushing system: The excavator sends the raw ore into the hopper with a trough feeder It can evenly send the material into the jaw crusher to crush the 210mm material to below 60mm Then, the output of the jaw crusher is transported to the next fine jaw crusher by the belt conveyor, which crushes to less than 20mm The output material is transported to the Gold CIP Processing Solution JXSC Machinery2024年10月27日 Shunzhi Mobile Crushing Plant With a compact structure and high portability, Shunzhi mobile crushing plant cut down 20% of the operation cost and increase 87% of transportation convenience Shunzhi mobile crusher plant has portable wheel type and crawler type crusher plant, which can be equipped with different types of crushers and auxiliary Mobile Crushing Plant For Sale Shunzhi Mining Machinery

.jpg)

Mobile Crushing Plant SMAT Philippines

Jaw Crusher With simple and firm structure, reliable operation, easy maintenance and service, and relatively low costs in production and construction, the SMAT jaw crusher is still widely used in coarse, medium, and fine crushing for various ores and rocks with compressive strengths ranging from 147 to 245 MPa in metallurgy, chemistry, building materials, electricity,